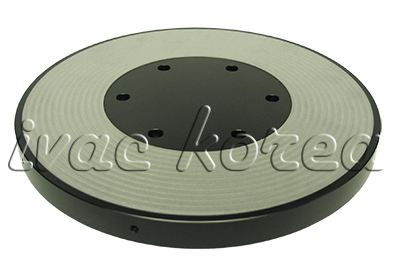

Wafer Gripper.

¤ýFeed pressure : 0.45 Mpa

¤ýFlatness : ¡¾5 § ¡ ¡¾20 §

¤ýShore D : 89

¤ýNoise level : 55 ~ 65 dBA

¤ýMaterial : PPS, AL, Ceramics

¤ýWorking temperatur : -20 ¡ 80 ¡É

¤ýelectrostatic condition : general, conductivity

¤ýprocess rate (%) : 10 ~ 30

¤ýcurve intensity(N/§±) : 28.5

¤ýcurve the modulus of elasticity(N/§±) : 14,498

WST60 & WST80 & WST100 & WST120 & WST 150 & WST200 & WST250

-Order No.

-characteristic of porous ceramic.

¤ýEven forming size or high surface area

¤ýAvailable in coating and fixation with various catalyst and functional material

¤ýOutstanding chemically resistant on acid and alkali

¤ýSafety with fine measurement

¤ýHigh heat resistance

¤ýFine wear resistance and corrosion resistance

¤ýNo more stain

¤ýReduce static electricity

¤ýAdjustable in adhesion with controlling a vacuum tube -Main material of porous ceramic. ¤ýAlumina

¤ýMullite ¤ýSilicin Carbide ¤ýProduceable for customer demand

¤ýLess aluminum causes weight lightening (specific gravity : 1.6 ~ 1.8)

-Main use.

¤ýmicrodroplet(bubble) generator

¤ýRemoval of heavy metals for water quality (Cr, Ni)

¤ýFilter for gas/liquid

¤ýChemical Support – Chemical support at high temperature when gas absorption

¤ýChemistry/biochemistry reactor

¤ýgas burner

¤ýMicro trapping system of bio-catalyst

¤ýVacuum chuck

¤ýIncrease liquidity efficiency by catalyst process

¤ýchromatography

¤ýSustainable in adhesion without distinction specific gravity

-Product Image.